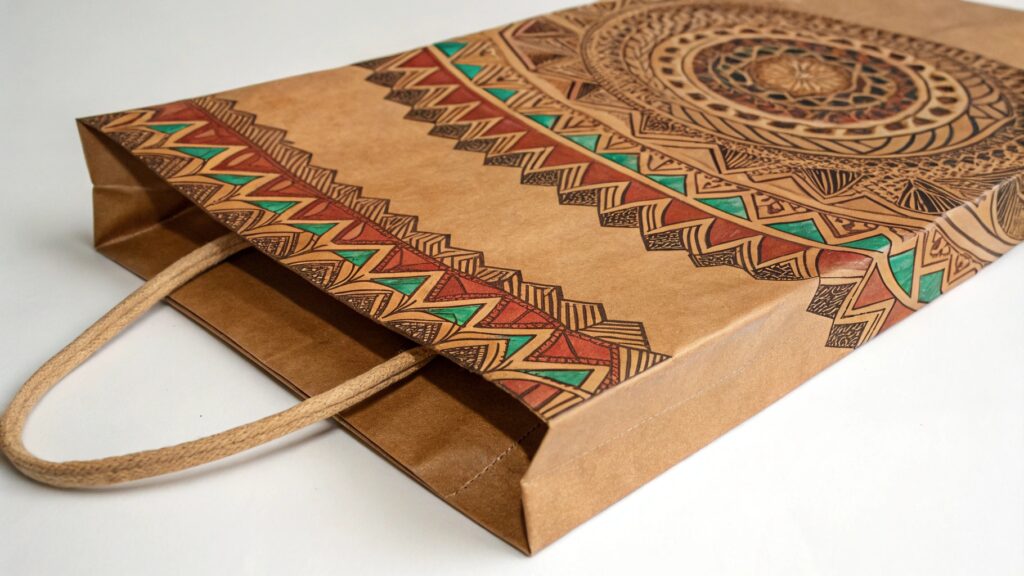

Are Brown Paper Bags Just Simple Packaging?

You see them everywhere, from cafes to boutiques. But are brown paper bags just a way to carry stuff? Or are they something more for your brand?

Brown paper bags are far more than simple packaging; they are a critical touchpoint for your brand, offering a unique opportunity to convey your values, enhance customer experience, and act as a silent ambassador for your business through thoughtful design and printing.

I’ve learned that in the busy world of eco-packaging, putting a custom logo on a paper bag might seem like a small detail. But it really means a lot for your brand. It's not just about putting a logo on kraft paper. It's about connecting your brand’s look with its green values, what customers experience, and how you market with touch.

How Can You Transfer Images onto Brown Paper Bags?

Want to put your unique design on a brown paper bag? You have an idea, but you are not sure how to make it real. Many people find transferring images confusing.

You can transfer images onto brown paper bags using various methods such as screen printing, heat transfer vinyl (HTV)1, direct-to-garment (DTG) printing, or sublimation, each offering different levels of durability, color vibrancy, and suitability for various fabric types.

When I help clients with their branding, tote bags often come up. They are a great way to spread your message. But choosing the right way to put your design on them is key. It's not just about the picture. It's about how that picture looks and lasts.

Choosing Your Image Transfer Method

Putting an image on a tote bag is more than just a craft project. It’s a branding choice. Each method has its own strengths and weaknesses. I've seen how picking the right one can make a huge difference in how professional your bags look. For instance, screen printing is great for bold, simple designs and large orders. It gives a durable, opaque finish. I often recommend it for logos that need to pop.

However, if you have a lot of colors or want to print photos, direct-to-garment (DTG) printing2 might be better. It works like an inkjet printer for fabric. The colors are very detailed. Heat transfer vinyl (HTV) is good for small runs or personalized items. It involves cutting a design from vinyl and pressing it onto the bag with heat. Sublimation is amazing for vibrant, full-color designs on polyester bags. The ink becomes part of the fabric.

| Transfer Method | Best Use Case | Pros | Cons |

|---|---|---|---|

| Screen Printing | Large batches, simple designs | Durable, vibrant colors, cost-effective for bulk | Limited colors, setup time |

| HTV | Small batches, personalized items | Easy for small runs, good opacity | Can feel thick, might crack over time |

| DTG Printing | Detailed images, small batches | High detail, many colors, soft feel | Higher cost per item, works best on cotton |

| Sublimation | Polyester bags, full-color images | Vibrant, soft feel, no cracking | Only works on polyester, light fabrics |

The real challenge isn't how to print. It’s how to print with a purpose. Choosing between these methods should not just be a technical choice. It should fit your brand's story and how many bags you need. I always ask clients about their goals. This helps us pick the best method for their brand and their budget. It also helps make sure the final product looks good and lasts a long time.

What Kind of Paper Can You Sublimate On?

Are you curious about sublimation3 and what materials it works on? You might have heard about it but are unsure if paper is an option. It is easy to get confused with all the printing terms.

You can sublimate on specially coated sublimation paper, which is designed to hold the sublimation ink and then release it as a gas when heat is applied, transferring the image onto polyester fabrics or specially coated hard surfaces, not directly onto regular paper.

I often get questions about sublimation because it creates such vibrant results. It’s a unique process. But it’s important to know that it is not like printing on regular paper. There is a specific kind of paper you need.

Understanding Sublimation Paper and Surfaces

Sublimation is a process where solid ink turns directly into a gas without becoming liquid first. This gas then dyes the fibers of a material. For this to work, you need special paper. This paper is coated to hold the ink and then let it go when heated. You do not sublimate directly onto regular paper bags or other paper products. The heat and ink need a specific kind of surface to bond with. I have seen many people try to sublimate on the wrong materials. It never works well.

The magic of sublimation happens when the ink leaves the special paper and merges with polyester fibers or a polymer coating. This means that to sublimate, your final product must be made of polyester or have a polyester coating. Common items include polyester apparel, mugs, phone cases, and keychains. These items are made to accept the sublimation ink. The image becomes part of the item, not just on top of it. This makes the design very durable. It will not crack or fade easily.

| Sublimation Component | Role in the Process | Importance |

|---|---|---|

| Sublimation Paper | Holds ink, releases as gas when heated | Essential for transferring ink accurately |

| Sublimation Ink | Special dyes that turn into gas | Designed to bond with polyester fibers |

| Heat Press | Applies heat and pressure for transfer | Activates the sublimation process |

| Polyester/Coated Surface | Receives the gaseous ink permanently | Ensures image permanence and vibrancy |

It is important to remember that sublimation is not for every material. It is a specific process for specific items. For instance, if you want to print on a cotton tote bag, sublimation is not the best choice. Other methods like screen printing or DTG would be better. Understanding these differences helps you make the right choice for your branding needs. It also helps you avoid wasting materials and time. This knowledge is key to getting the best results.

Can I Heat Press on Paper Bags?

You have a heat press and paper bags. You might think it is a simple combination. But can you really use a heat press on paper bags without issues?

While you can technically apply some heat transfer materials to paper bags using a heat press, it is generally not recommended as paper can easily scorch, wrinkle, or tear under the heat and pressure, and the results are often not durable or professional looking compared to other printing methods.

I've been asked this many times. People see the heat press and think it can do anything. But when it comes to paper bags, it's a bit more complicated. It is not as simple as putting a design on a t-shirt.

Why Heat Pressing Paper Bags is Tricky

Applying heat and pressure to paper is risky. Paper is much more delicate than fabric. When you use a heat press, the high temperature can scorch the paper. This leaves burn marks. The pressure can also wrinkle or tear the bag. This makes your custom design look bad. I have seen many attempts that ended with damaged bags. The results are often not professional. They are also not very durable. The design might peel or crack quickly.

Instead of heat pressing, other methods are better for paper bags. Flexography, screen printing, digital printing, and hot foil stamping are all designed for paper. They give much better results. These methods are made to work with the paper's properties. They ensure the print looks good and lasts. For example, digital printing is great for small orders and detailed designs. Screen printing is good for bold logos. Hot foil stamping gives a premium, shiny look.

| Printing Method | Why It's Better Than Heat Pressing for Paper Bags | Typical Use Case |

|---|---|---|

| Flexography | High-speed, cost-effective for large volumes | Retail bags, food packaging |

| Screen Printing | Vibrant, opaque colors, durable | Bold logos, simple designs |

| Digital Printing | Detailed graphics, small batches, flexibility | Custom designs, variable data |

| Hot Foil Stamping | Premium, metallic finish, luxurious feel | High-end brands, special editions |

The key is to match your printing method to your brand story and how many bags you need. Choosing between these should not just be a technical choice. It should fit your brand's story and your production volume. I always advise my clients to pick a method that creates the best impression. This is much more important than just trying to use equipment you already have. Your bag will often be your customer's first physical interaction with your brand. Making it look good is important.

Conclusion

Brown paper bags are powerful brand tools. Choose printing methods wisely to tell your brand's story and connect with customers.

-

Learn about HTV, its benefits, and how it can elevate your crafting projects with personalized designs. ↩

-

Discover the advantages of DTG printing for detailed designs and small batches, perfect for custom apparel. ↩

-

Explore this link to understand the sublimation process, its applications, and why it's ideal for vibrant designs on polyester. ↩