Is canvas bag printing still a good idea for brands?

I’ve seen canvas bags go from simple totes to fashion statements. It makes me wonder, are they still a powerful branding tool today?

Canvas bag printing is more relevant than ever. It's a key way for brands to show they care about the environment and design. A well-printed canvas bag acts as a moving ad, showing off a brand's style and values in a strong way.

When I worked in the printing factory, canvas bags were always popular. Now, they are about telling a story. It's about making a statement that lasts.

How do you print on a canvas bag?

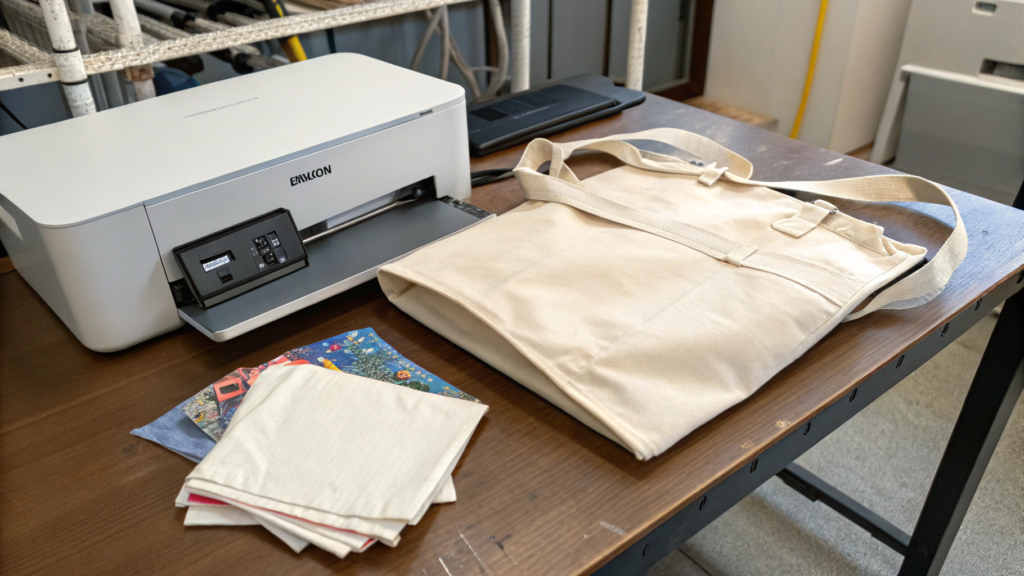

Do you want to put your design on a canvas bag? Many people ask me how this process works. There are a few good ways to do it.

Printing on a canvas bag usually involves methods like screen printing, direct-to-garment (DTG) printing, or heat transfer1. Each method offers different benefits for design detail, durability, and cost, depending on your specific needs.

From my experience, choosing the right printing method is key. It changes how your design looks and how long it lasts. It's not just about putting ink on fabric. It's about matching the right technique to your vision.

What are the main ways to print on canvas?

When I advise clients on canvas bag printing, I explain the different methods. Each has its own strengths. Screen printing is great for simple designs and large orders. It makes colors pop. Direct-to-garment (DTG) printing is better for complex designs with many colors, like photos. It's like printing on paper, but on fabric. Heat transfer uses heat to press a design onto the bag. This is good for small orders or special effects. Knowing these helps you pick what's best for your brand.

| Method | Best For | Pros | Cons |

|---|---|---|---|

| Screen Printing | Simple logos, large quantities, vibrant colors. | Durable, cost-effective for bulk, bright colors. | Limited color gradients, higher setup costs for small runs. |

| Direct-to-Garment (DTG) | Complex designs, photos, small quantities. | High detail, wide color range, soft feel. | Slower for large orders, lighter colors might not be as vibrant. |

| Heat Transfer (Vinyl/Sublimation) | Small batches, personalized items, special finishes. | Good for intricate details, versatile, good for unique designs. | Can feel stiff, less durable over time than screen printing2. |

I once helped a client with a new product launch. They needed bags with a detailed photo. Screen printing would have been too costly and hard for that design. So, we went with DTG printing. The bags looked amazing. The photo came out clear and bright. This made the bags more than just a giveaway. They became a piece of art that people loved to carry. It shows how picking the right method really matters for the final look.

Can I print directly from canvas?

Are you asking if you can simply put a canvas bag into a printer? It's a common question, and the answer is usually no. Regular printers don't work for fabric like they do for paper.

You cannot print directly from a standard home or office printer onto a canvas bag. Special industrial-grade printers, like those used for direct-to-garment (DTG) printing, are needed to apply ink directly onto fabric effectively and permanently.

When I first started, people sometimes tried to use paper printers for fabric. It never worked well. Fabric needs different kinds of ink and different ways of putting it on. It's a specialized process.

Why do you need special printers for canvas?

Printing on canvas is different from printing on paper. Canvas is a fabric, and it absorbs ink differently. Regular printers use inks meant for paper. These inks would bleed or wash out on fabric. Specialized printers, like DTG printers, use textile inks. These inks are designed to bond with fabric fibers. They also have special mechanisms to feed the fabric smoothly. This ensures the print is clear, vibrant, and lasts through washes. Without these special tools, the print would not look good or last long.

| Aspect | Regular Paper Printer | Specialized Fabric Printer (e.g., DTG) |

|---|---|---|

| Ink Type | Water-based, pigment, or dye inks for paper. | Textile-specific inks (pigment or reactive dyes) designed to bond with fabric. |

| Ink Absorption | Designed for paper's specific absorption. | Optimized for fabric's varied absorption rates and fiber types. |

| Print Head | Fine nozzles for crisp lines on smooth paper. | Larger nozzles to handle thicker textile inks and prevent clogging on fabric. |

| Fabric Handling | Not designed to feed or hold fabric properly. | Features a flatbed or conveyor system to hold fabric flat and move it precisely. |

| Durability | Prints would smudge or wash off fabric. | Prints are durable, washable, and resistant to fading. |

| Drying/Curing | Air-dries quickly on paper. | Requires heat curing (e.g., heat press) to set ink into fabric fibers. |

I remember a small business owner who tried to print their own bags with a desktop printer. The results were messy and faded quickly. When they came to me, I showed them how DTG printing could achieve sharp, lasting designs. They were amazed by the difference. It just proves that for quality results on fabric, you need the right equipment. It’s an investment in your brand’s image.

How do I transfer a photo to a canvas bag?

Do you have a favorite photo you want on a canvas bag? It's a great idea for a unique gift or personal item. There are ways to do this, even at home.

To transfer a photo to a canvas bag, you can use iron-on transfer paper for a DIY approach, or choose professional methods like direct-to-garment (DTG) printing for a high-quality, durable result.

I've seen many ways people try to get photos onto fabric. For personal use, some home methods work fine. For business, professional printing is usually best. It depends on the look and feel you want.

What are the best ways to get photos onto canvas bags?

Getting a photo onto a canvas bag can be done in a few ways. For a DIY project, you can use iron-on transfer paper. You print your photo onto this special paper with a regular inkjet printer. Then, you iron it onto the bag. This is good for one-off personal items. For professional quality, Direct-to-Garment (DTG) printing is the best option. It prints the photo directly onto the fabric, giving a soft feel and clear image. This is what I recommend for businesses or if you want many bags.

| Method | Best For | Pros | Cons |

|---|---|---|---|

| Iron-On Transfer Paper | Home projects, small batches, personal gifts. | Affordable, easy to do yourself with a home iron. | Can crack or fade over time, less durable, slight plastic feel. |

| Direct-to-Garment (DTG) Printing | High-quality photos, detailed images, soft feel. | Excellent detail and color range, durable, breathable print. | Can be more expensive for small runs, requires professional equipment. |

| Sublimation Printing | White or light-colored polyester canvas bags (not pure cotton). | Vibrant colors, durable, becomes part of the fabric, no feel. | Only works on polyester or polyester-coated materials; colors can be dull on cotton. |

I helped a client who wanted to create custom bags with pet photos for a charity event. They first tried iron-on transfers at home, but the quality wasn't good enough for selling. When they came to me, we used DTG printing. The photos were crisp and the colors vibrant. The bags sold out quickly. This experience showed me how professional methods really elevate the final product. It makes the bag a cherished item, not just a simple transfer.

Conclusion

Canvas bag printing is a powerful way to show your brand. You can choose from screen printing, DTG, or heat transfer. The best way to print depends on your design and needs.